CNC Press Brake Machine Supplier solutions are becoming increasingly significant in the manufacturing industry, particularly for companies seeking precise metal forming capabilities. As industries evolve, the challenges of production efficiency and accuracy have amplified. A CNC press brake machine addresses these issues seamlessly, ensuring that businesses achieve high-quality results in sheet metal fabrication. By leveraging advanced technology, manufacturers can streamline their processes, reduce waste, and increase output. This article will dive deep into the workings and benefits of CNC press brakes while answering crucial questions about their applications and operational significance.

What is a CNC Press Brake Machine?

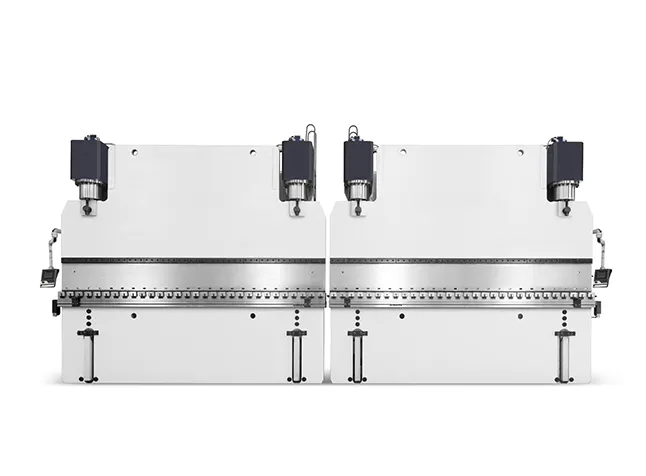

A CNC press brake machine is a sophisticated piece of machinery utilized in bending and shaping sheet metal. Unlike traditional machines, CNC (Computer Numerical Control) versions employ computer programming, allowing for precise control over the bending process. This machine typically features multi-axis control, which is crucial for executing complex bends that are otherwise difficult to achieve. A 2022 report from the "Fabricators and Manufacturers Association" highlights that such machines enhance productivity by approximately 25% compared to manual presses.

Key Industry Terms:

CNC (Computer Numerical Control): Technology that automates machine tools through programmed commands, allowing for high precision and repeatability.

Multi-axis Control: Enables movement along multiple axes, providing added flexibility for complex shapes.

Bending Radius: The smallest radius one can achieve without compromising material integrity, critical for ensuring product durability.

Application Scenarios of CNC Press Brake Machines

CNC press brakes are versatile and find applications across multiple sectors, including:

Automotive Manufacturing: They are used for creating chassis components, brackets, and panels with high accuracy.

Aerospace Industry: CNC press brakes shape lightweight yet strong components, crucial for aerodynamics and safety.

Construction: Metal framing and supports often require bending, wherein these machines play an essential role.

Furniture Manufacturing: Innovatively designed metal furniture pieces often necessitate complex bending processes that CNC machines accurately perform.

The varied application of CNC press brake machines reflects their adaptability and importance across industries, marking them as indispensable tools in modern manufacturing.

Advantages of Using CNC Press Brake Machines

The significance of CNC press brake machines lies in their numerous advantages:

Precision: CNC technology allows for high accuracy, with tolerances often within ±0.005 inches, resulting in reduced waste and rework.

Speed: A study revealed that CNC machines can complete intricate bends in 30% less time compared to manual processes, allowing for faster project turnover.

Consistency: Automated processes lead to uniform output, ensuring each product meets strict quality control standards.

Flexibility: With multi-axis control, these machines can execute complex designs that might be impossible to replicate manually.

Investing in CNC press brakes not only enhances operational efficiency but also positions manufacturers as leaders in their respective industries.

Next Steps for Interested Users

To better understand the workings and benefits of CNC press brake machines, prospective buyers are encouraged to refer to the user guide provided by their CNC press brake supplier. Familiarizing oneself with the operation and maintenance of these machines can significantly boost productivity and ensure optimal performance.

Frequently Asked Questions (FAQ)

1. How does multi-axis control enhance the CNC press brake's functionality? Multi-axis control allows the press brake to bend in multiple dimensions, providing greater flexibility in production and enabling the creation of complex geometries.

2. What materials can be processed with a CNC press brake machine? CNC press brakes can handle various materials, including aluminum, steel, and stainless steel, accommodating different thickness ranges.

3. How is the accuracy of a CNC press brake machine ensured? Accuracy is ensured through precision components, advanced CNC programming, and regular calibration of the equipment.

4. Are CNC press brake machines suitable for small-scale production? Yes, they are efficient for both high-volume and small-scale production runs, providing cost-effective solutions across different manufacturing needs.

Conclusion

In conclusion, CNC press brake machines play a vital role in modern manufacturing, significantly improving efficiency and precision. The integration of multi-axis control systems adds to their versatility, allowing manufacturers to execute complex designs that enhance product offerings. Companies like BOST offer a range of solutions for CNC press brake machines, making them a valuable partner for anyone looking to elevate their manufacturing capabilities. Interested users should consider exploring this advanced technology further to leverage its full potential in their operations.