In the competitive landscape of manufacturing, the CNC Press Brake Machine has emerged as a pivotal tool for precision metal forming. As industries strive for increased efficiency and accuracy, finding a reliable CNC Press Brake Machine Supplier has become crucial. This technology not only addresses the pain points of inaccurate bends and inconsistencies in metalwork but also enhances productivity, significantly reducing operational costs. As a result, manufacturers are now able to meet tight deadlines with high-quality outputs, redefining industry standards.

What is a CNC Press Brake Machine and How Does it Work?

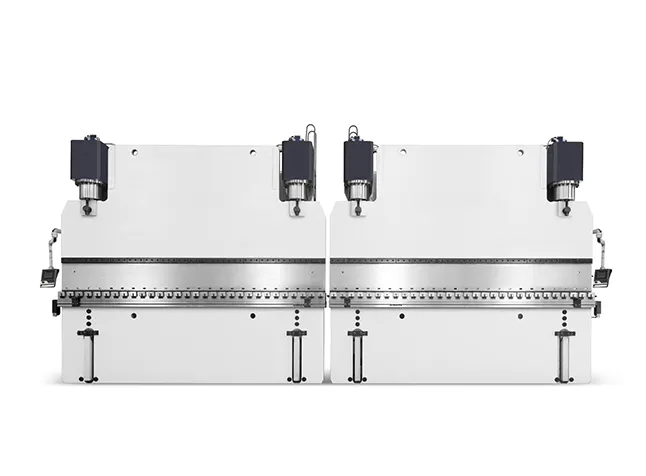

A CNC Press Brake Machine is a programmable tool used for bending sheet and plate material. Essentially, it employs a mechanical means to apply force to a specific section of a workpiece to create the desired angle or curvature.

Definition:

At its core, a CNC (Computer Numerical Control) Press Brake Machine is a device that utilizes CNC technology to manage the bending process. This method uses programmed commands to control various functions, such as the pressure applied, the bending angle, and the length of the material being manipulated.

Industry Term Analysis:

CNC Technology: This refers to the computer-controlled process that allows for high-precision operations, which is essential in modern manufacturing. According to a report from the International Federation of Robotics, the usage of CNC machines has increased by 75% from 2015 to 2020, highlighting their importance in automation.

Bending Force: The force applied to bend the material, which varies depending on the thickness and type of material. Manufacturers can measure this force through advanced sensors integrated into the machinery.

Material Thickness: Not only influences the bending process but also determines the required bending force. The American Society of Mechanical Engineers (ASME) states that calculating the right formula for bending can lead to a 30% improvement in product quality.

Application Scenarios:

CNC Press Brake Machines are widely utilized across various industries, including:

Automotive: For creating components like brackets, frames, and enclosures, which require high accuracy and consistency.

Aerospace: In the fabrication of parts that meet regulatory standards, often needing complex geometries.

Construction: To produce structural components such as beams and columns that withstand significant stress.

For instance, a study published by MetalForming Magazine showed that the integration of CNC Press Brake Machines in the automotive sector resulted in a 40% reduction in material waste due to precise bending techniques.

Brief Description of Advantages:

Understanding the advantages of purchasing from a CNC Press Brake Machine Supplier can streamline manufacturing processes:

Precision: CNC machines offer an accuracy of ±0.01mm, ensuring that machining meets stringent specifications.

Cost Efficiency: The automation of processes reduces labor costs by up to 25%, as operators can manage multiple machines simultaneously.

Versatility: These machines can handle a variety of materials, from aluminum to stainless steel, making them a one-stop solution for different manufacturing needs.

Reduced Lead Time: Actual measured lead time for projects using CNC Press Brake Machines can be reduced from weeks to just a few days, allowing manufacturers to meet market demands swiftly.

Next Step Guidance:

To further understand the operational capabilities and detailed functionalities of CNC Press Brake Machines, we recommend reading the user guides provided by CNC machinery manufacturers, including BOST. This guide will explain recommended practices, maintenance tips, and how to optimize performance for your specific needs.

FAQs

What is the typical cost of a CNC Press Brake Machine?

The price can range between $10,000 and $500,000, depending on the machine's specifications, size, and capabilities.

How does maintenance affect operational efficiency?

Regular maintenance can lead to a 20% increase in operational efficiency by preventing machine downtimes and ensuring consistent performance.

Can CNC Press Brake Machines fabricate complex shapes?

Yes, modern CNC Press Brake Machines are equipped to handle complex profiles with ease, improving the design capabilities of manufacturers.

What features should I look for in a CNC Press Brake Machine?

Key features include programmable control software, safety mechanisms, and high tonnage capacity for effective bending across various material thicknesses.

In conclusion, the integration of a CNC Press Brake Machine within your production line can substantially improve your manufacturing process, ensuring precision and efficiency that meets the growing demands of the industry. Consider reaching out to reliable suppliers like BOST to explore advanced CNC Press Brake options tailored to your business needs.