Related Products

Compared to conventional options, CNC press brakes offer smarter, faster bending — increasing output by up to 30% without compromising accuracy.

Model: BTCNC

Controller Brand: DELEM, CYBELEC, ESA

Capabilities: 50T - 1000T

NC press brakes are a smart, economical choice - offering high value at a lower cost compared to more advanced systems.

Model: BTNC

Controller Brand: ESTUN, DELEM, CYBELEC, ESA

Capabilities: 30T - 600T

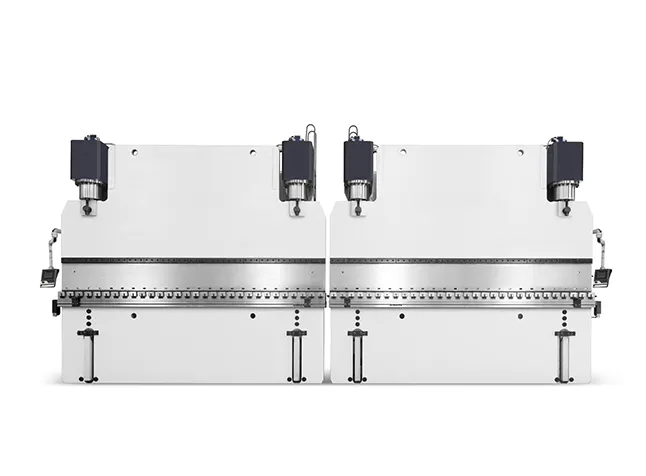

The dual-machine synchronized press brake provides enhanced versatility, allowing combined operation for bending longer components or independent use for separate tasks, delivering higher manufacturing value and flexibility.

Model: 2-BTCNC

Controller Brand: DELEM, CYBELEC, ESA

Capabilities: 120T - 1600T

Bending centers are built for smart, flexible manufacturing. With fully automated bending processes, they deliver exceptional efficiency and precision — especially for small-batch, high-mix production. Ideal for modern sheet metal workshops, they reduce labor dependency, shorten setup times, and adapt quickly to changing orders.

Model: BTP

Controller: Independent R&D

Capabilities:3mm*2500mm

The all-electric servo press brake combines precision, efficiency, and sustainability in one smart solution. Its compact and agile design makes it the perfect choice for precision sheet metal, small appliance enclosures, and high-accuracy mechanical parts. With faster performance, greater accuracy, and clean electric power, it sets a new standard for modern, eco-friendly manufacturing.

Model: BTE

Controller: DELEM, CYBELEC, ESA

Capabilities: 4T-63T

The fully automatic tube bending machine features easy operation and high efficiency, ensuring precise and consistent bending for mass production while reducing labor costs through automatic feeding and calibration functions.

Model: CNC-pipe

Capabilities: 6mm - 219mm

The semi-automatic tube bending machine features a simple structure and flexible operation, making it suitable for diverse production needs, with lower cost and easy maintenance ideal for small to medium-sized businesses, while still delivering stable bending quality for small to medium batch production.

Model: NC-pipe

Capabilities: 6mm - 219mm

Single Table Fiber Laser Cutting Machine

Single-platform laser machines offer integrated high-precision cutting with improved efficiency and reduced setup time, making them ideal for streamlined production.

Model: BTS

Laser Power: 1KW - 60KW

Processing Area: 3000*1500~24000*3200mm

Dual-use Fiber Laser Cutting Machine

The combined sheet and tube laser machine provides versatile, high-precision cutting for both flat plates and tubes in one setup, greatly enhancing efficiency and space utilization.

Model: BTDU

Laser Power: 500 - 6kW

Tube Diameter: 20-320mm

The laser tube cutting machine delivers precise, efficient, and clean cuts with minimal material waste, ideal for complex tube fabrication.

Model: BTT

Laser Power: 1kW - 60kW

Tube Diameter: 20-320mm

Ground-Rail Laser Cutting Machine

The ground-rail laser cutting machine offers stable, high-precision cutting with smooth motion and large processing capacity, ideal for heavy-duty and large-format materials.

Model: BTG

Laser Power: 500 - 6kW

Tube Diameter: 20-320mm