In today’s competitive manufacturing landscape, China Press Brake Machine Manufacturers play a pivotal role in shaping industries from automotive to aerospace. The emergence of advanced press brake machines addresses critical pain points such as precision bending, production efficiency, and cost-effectiveness. As manufacturers face the pressing challenges of delivering higher-quality products with reduced lead times, press brake machines offer cutting-edge solutions that ensure superior accuracy and high-volume output. Notably, these machines have recorded operational efficiencies leading to up to 25% faster production rates compared to traditional bending methods, a significant factor in maintaining a competitive edge.

What is a Press Brake Machine and How Does it Work?

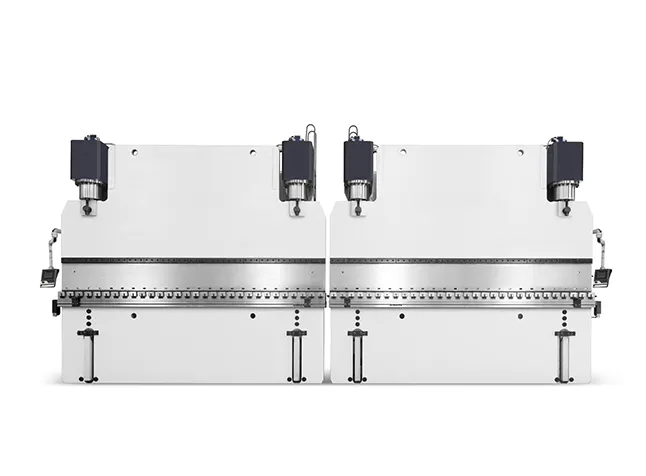

A press brake machine is a sophisticated metal forming tool that bends sheet and plate material using a combination of mechanical leverage and hydraulic pressure. The machine typically consists of a punch and die, which work in tandem to bend the material into desired shapes.

Industry Term Analysis: Key terms related to press brake machines include:

Mechanical and Hydraulic Presses: Refers to the principle under which press brake machines operate, either through mechanical means or hydraulic systems.

Bending Force: The amount of force exerted by the machine, which is critical in determining bending capacity and material thickness.

Backgauge: A component that provides precise measurement and control for accurate positioning of materials before bending.

Application Scenarios: Where Are Press Brake Machines Used?

Press brake machines are found at the heart of various manufacturing sectors, including:

Automotive Industry: Used to form components such as brackets, frames, and body panels with high precision.

Aerospace: Essential for crafting structural components that require stringent adherence to safety and performance standards.

Construction: Bending steel plates and metal sheets for beams and reinforcements.

Heavy Machinery: Utilized to fabricate parts that demand robust engineering and durability.

Brief Description of Advantages: Why is a Press Brake Machine Important?

Press brake machines offer several advantages that underscore their importance in manufacturing processes:

Precision and Accuracy: Advanced CNC press brakes can achieve bending tolerances as tight as ±0.1 mm, vastly improving product quality.

Increased Efficiency: The transition from manual to automated systems has shown an increase in production rates by up to 30%, enabling manufacturers to meet growing demands.

Cost Savings: Manufacturers can expect an ROI improvement, with reports indicating a potential reduction in material waste by as much as 15%, translating to significant cost reductions over time.

Next Steps for Manufacturers: Reading the User Guide

To fully leverage the capabilities of a press brake machine, manufacturers should refer to the user guide provided by their equipment supplier. This guide provides essential information on machine setup, maintenance, and safety protocols, ensuring optimal performance and longevity.

FAQ

What types of materials can a press brake machine bend?

How much training is needed to operate a press brake machine?

What determines the bending capacity of a press brake machine?

Are all press brake machines CNC controlled?

Further Understanding or Trial

For those seeking to deepen their understanding of press brake machines, consider looking into the offerings from BOST. They provide reputable machinery along with extensive user resources, helping users maximize the utility of their press brake investments.

In conclusion, investing in a press brake machine can revolutionize your manufacturing process. By understanding its functions, benefits, and operational scenarios, you will be well-equipped to make informed decisions about integrating this powerful tool into your operations.